I want to make the outer wall resistant to dirt, and reduce the cost of cleaning and repairing it.

Background

-

The exterior walls of buildings such as condominiums, buildings, and detached houses accumulate dirt over time, which not only impairs the appearance, but also causes deterioration over time and greatly reduces the value of the building itself. Renovation work, which is carried out every 10 to 15 years, restores the beauty of the building to some extent, but cleaning and repainting the exterior walls can be costly and time-consuming.

Making the exterior walls less dirty, preventing deterioration, and reducing the cost of cleaning and repairing them is one of the major challenges for building owners and design firms, but effective long-term maintenence has always been a challenge. There have been few coatings that have proved to be highly durable for exterior walls until now.

Solutions

8H Dirt-repellent Coating for Masonry and Porous Materials / 8H Dirt-repellent Coating for Masonry and Porous Materials (Hydrophobic)

-

SOFT99's 8H Dirt-repellent Coating for Masonry and Porous Materials is a dirt repellent coating agent for exterior walls that exhibits impressive results, repelleing dirt from the exterior walls of buildings for an extended period of time.

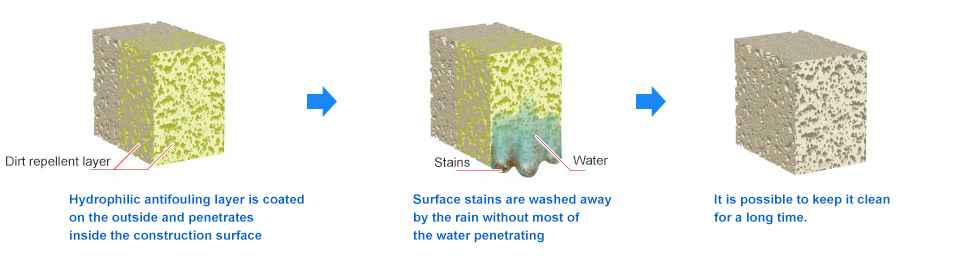

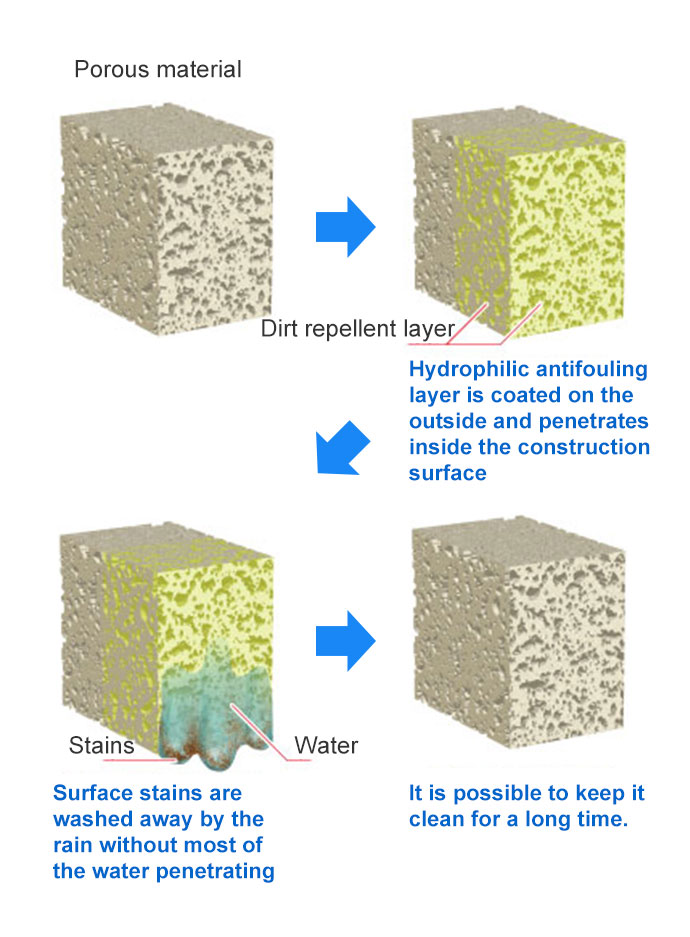

When the "8H Dirt-repellent Coating for Masonry and Porous Materials" is applied to inorganic porous materials such as porcelain tiles, mortar, and concrete, the hydrophilic dirt repellent layer is firmly formed not only on the construction surface but also penetrating inside the construction surface. As a result, rainwater is prevented from entering into the inside of the outer wall, and dirt is washed away with rain, so the beauty of the surface is maintained. The coating produces a dense and very hard coating (equivalent to 8H surface hardness), which provides long-term high-quality performance.

Because of the inorganic properties of the coating, there is little deterioration of the coating surface due to light, heat, water, etc., and due to the porous nature of the coating, the appearance does not change and there is moisture permeability. Since the coating only needs to be applied once without a base treatment, the process is very quick.

At the present time, the dirt repellent performance, durability performance, and work performance have been proved effective, and the "8H Dirt-repellent Coating for Masonry and Porous Materials" has begun to be adopted in a lot of newly built properties.

- Diagram of dirt repellent layer formation (8H Dirt-repellent Coating for Masonry and Porous Materials)

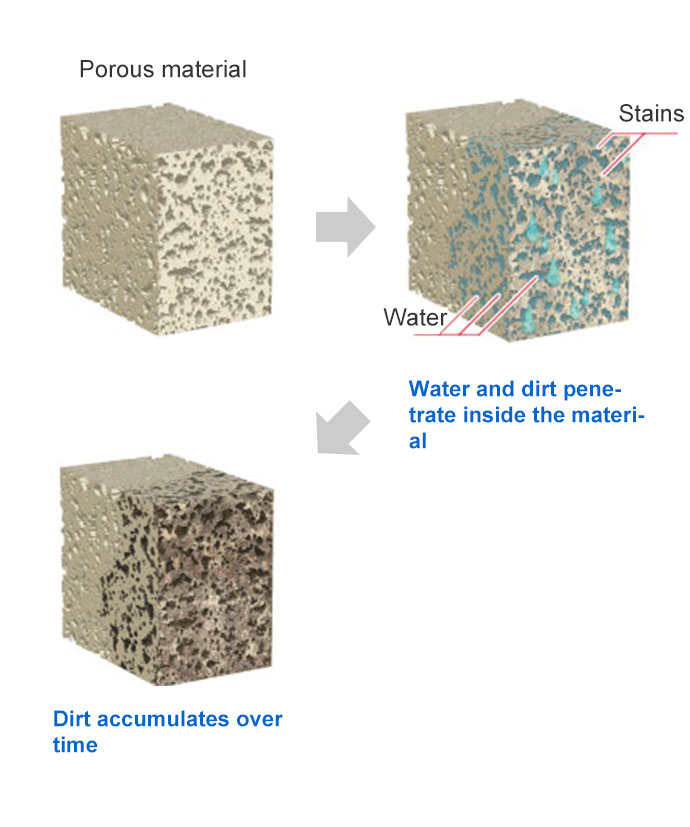

- Porous material

- Porous material

-

8H Dirt-repellent Coating for Masonry and Porous Materials application

- * The dirt repellent layer is transparent, but it is expressed in light yellow for the explanation.

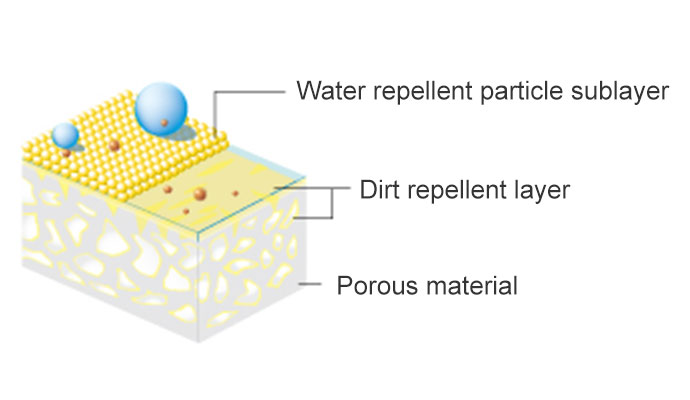

- Diagram of dirt repellent layer formation (8H Dirt-repellent Coating for Masonry and Porous Materials)

- Porous material

- 8H Dirt-repellent Coating for Masonry and Porous Materials application

- * The dirt repellent layer is transparent, but it is expressed in light yellow for the explanation.

- Target materials

-

・ Porcelain tiles

・ Mortar

・ Concrete

8H Dirt-repellent Coating for Masonry and Porous Materials (Hydrophobic)

-

The “Hydrophobic” version of 8H Dirt-Repellent Coating contains extremely water repellent particles for even more effective dirt-repellent properties.

The coating becomes super water repellent immediately after drying, but over time, the dirt repellent layer is completely cured, forming a hydrophilic layer with excellent long-term dirt repellent properties on the porous surface. The hydrophobic particles on the surface are lost naturally after about half a year due to rainfall, but those that penetrate the porous surface remain, making it difficult for dirt to penetrate the material. -

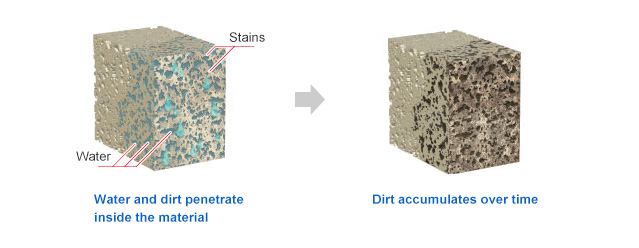

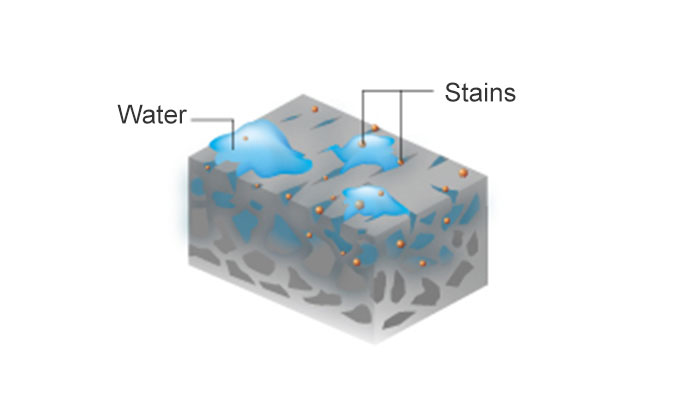

- Without application

Water and dirt penetrate the material, and dirt remains inside.

Water and dirt penetrate the material, and dirt remains inside. - 8H Dirt-repellent Coating for Masonry and Porous Materials (Hydrophobic)

The crosslinking reaction forms a dense and strong dirt repellent layer the structure, so water hardly penetrates and no dirt sticks to the surface.

The crosslinking reaction forms a dense and strong dirt repellent layer the structure, so water hardly penetrates and no dirt sticks to the surface.

Results

- Advantages of 8H Dirt-repellent Coating for Masonry and Porous Materials

-

The current state of the outer wall Advantages of 8H Dirt-repellent Coating for Masonry and Porous Materials Rainwater penetrates Rainwater does not penetrate Dirt accumulates Dirt does not accumulate Deterioration due to ultraviolet rays Breathable and no gloss on the surface The beauty of the surface cannot be maintained Prevents deterioration due to ultraviolet rays, acid rain, and salt damage Maintains a clean and good condition Maintenance and repair costs can be reduced Easy to apply (one-time coating) and economical

-

- Comparison of a wall coating (2 years after application)

-

Without 8H Dirt-repellent Coating for Masonry and Porous Materials

The dirt spreads across the wall and there are visible rain marks.

-

With 8H Dirt-repellent Coating

for Masonry and Porous Materials

Even if some dirt accumulates, it can be removed by easily.

-

- Comparison on concrete (10 years after application)

Without 8H Dirt-repellent Coating for Masonry and Porous Materials

Dirt and mold accumulate easily and are hard to remove.

-

With 8H Dirt-repellent Coating

for Masonry and Porous Materials

The sturdy dirt repellent layer keeps the aesthetic and cleanliness from deteriorating for a long time.

Performance test

-

1. Weather-resistant ability

It has excellent acid resistance and alkali resistance, and prevents deterioration due to acid rain and salt damage over a long period of time.

The application of "8H Dirt-repellent Coating for Masonry and Porous Materials" maintains a state close to the original with little change in colour tone after 2000 hours. -

Weather-resistant ability test

The colour tone before application is "100", and the degree of fading over time is shown.

-

2. Dirt repellent performance

The crosslinking reaction forms an dirt repellent layer (equivalent to pencil hardness 8H) of the three-dimensional network structure, and the dirt repellent performance is sustained for a long period of time without the accumulation of dirt.

The application of "8H Dirt-repellent Coating for Masonry and Porous Materials" shows that it does not easily get dirty. -

Dirt repellent performance test

The degree of contamination was measured when the test material was sprinkled with 15 kinds of dirt and dust with a colour difference meter

-

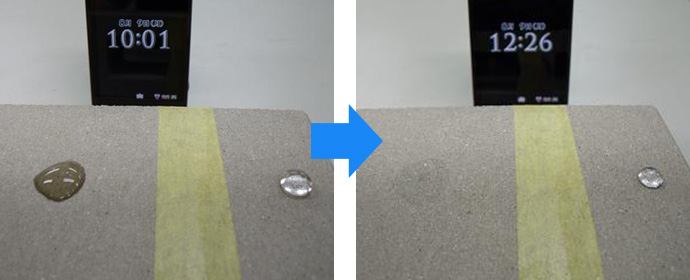

3. Anti-penetration performance

Even if water droplets such as rain accumulate, it hardly penetrates the material, and which prevents the adverse effect of water damage.

The painted surface on the left has been discoloured by the water droplet, and over time it has completely disappeared and has been aborbed by the material, but the coating surface on the right can be seen to have no water discolouration, no absorption and no change. -

Anti-penetration performance test

The unpainted portion of the "hard coating porcelain tile" on the concrete plate (left side) and the painted part (right) each had 0.5cc water dropped on the surface, and the subsequent water droplets were observed over time.

Construction results

-

- Building name:

- Ginza Ito Building

- Application day:

- December 10, 2010

- Application target:

- Granite and brick tiles

- Application surface:

- 800m2

- Construction method:

- Spray and brushing

- Design company:

- Octem Design Co., Ltd.

-

- Building name:

- Nursing Home Le Rave Omiya Kita

- Application day:

- April 2011

- Application target:

- Concrete release unit

- Application surface:

- 100m2

- Construction method:

- Spray and brushing

- Design company:

- Alli Design Co., Ltd.

-

- Building name:

- Private home in Orchid Hills

- Application day:

- August 2011

- Application target:

- Painted walls, concrete parts, etc.

- Application surface:

- 600m2

- Construction method:

- Spray

- Design company:

- Namikawa Real Estate Sales Co., Ltd.