- Water marks (after 18 months outdoors)

-

Uncoated

Coating

- Gloss retention (after 18 months outdoors)

-

Uncoated

Coating

The deterioration of vending machines not only leads to a decline in the image of beverage manufacturers, but also causes a variety of problems, such as a decline in product sales and claims from vending machine location owners. Due to this, beverage manufacturers and vendors are focusing on cleaning up products and regularly replacing vending machines.

However, the replacement of vending machines is expensive, costing around ¥300,000 per unit, with repainting alone costing about ¥10,000. The reduction of the maintenance cost was one of the major concerns of beverage manufacturers and vendors.

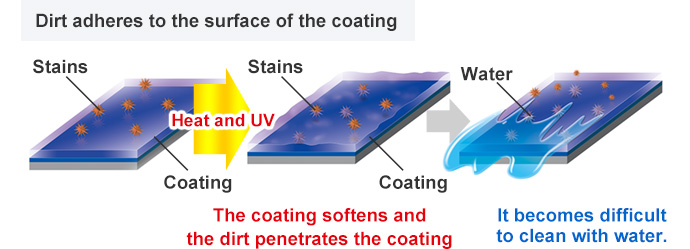

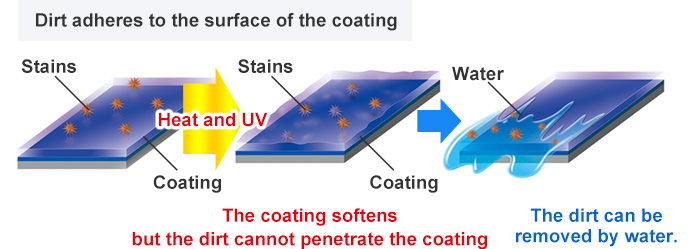

SOFT99's "H-7 Glass Coat for Vending Machines" prevents dirt accumulation on vending machines. The coating performance greatly reduces the frequency and labor of maintenance.

The application of SOFT99's H-7 Glass Coat for Vending Machines has not only increased the aesthetics of vending machines, but has cut maintenence time down significantly. Whereas before it took 20 to 30 minutes to carry out maintence, it now can be done in less than 5 minutes. In addition, cost of coating is very well recieved, as we can reduce the material and construction costs to about 3,000 to 4,000 yen per unit.

| Current State of Vending Machines | Advantages of applying the glass coating |

|---|---|

| The unit gradually becomes very dirty | Dirt does not accumulate |

| Owners often request to replace machine due to dirtiness | Just wipe it with a wet towel even if it gets dirty (can be completed in 2-3 minutes) and maintain a clean state for a long time |

| It is difficult to clean by hand and it takes a long time. →Less units able to be cleaned in one period. |

Significantly reduce the extra time of op-ed sales →Significantly more units able to be cleaned in one period. |

| Decrease in sales volume due to dirtiness | Sales volume increases as the units are in a clean state all the time |

| Decrease in corporate image due to dirt | Because dirt does not accumulate on the vending machine, maintenance is easy and expenses are reduced → repainting is unnecessary |

| Improving the company's image with clean vending machines | |

| Replacement of vending machines has decreased and expenses have been drastically reduced | |

| Differentiation from other vending machines in large locations | |

| Significant reduction in long-term vending machine maintenance costs |

| Criteria | Uncoated | Coating | ||

|---|---|---|---|---|

| Test points | Water marks | Gloss retention | Water marks | Gloss retention |

| 1st test (2006.5.31) | ○ | ○ | ○ | ○ |

| 2nd test (2007.5.16) | △~× | △ | ○ | ○ |