I want to print on poorly adhesive materials.

Background

-

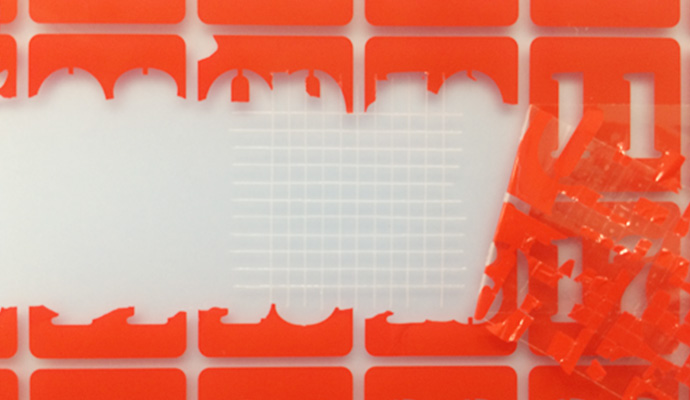

It is a recognised industry problem that plastics and glass materials such as acrylics, polypropylenes, and polycarbonates are difficult to print on. Due to this, printing on these materials requires base treatments and primers, which can take a lot of time. In addition, generally the ink does not adhere cleanly to the material's surface, sometimes smudging, peeling or running, or is tainted by something as simple as rubbing the surface. Also, the appearance of the material is often changed by the base treatment, which may result in problems such as the quality of the material being lost.

Solutions

-

FlameBond

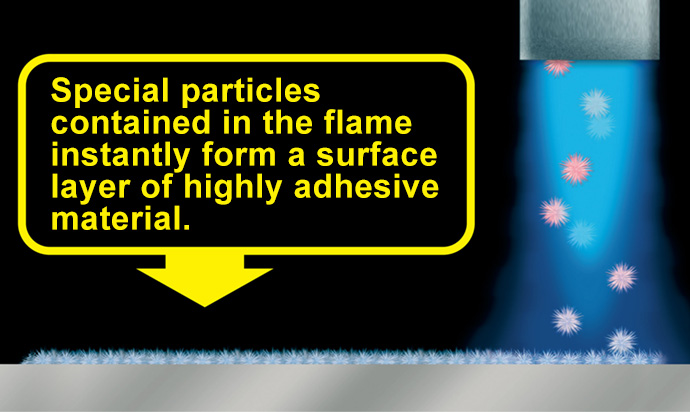

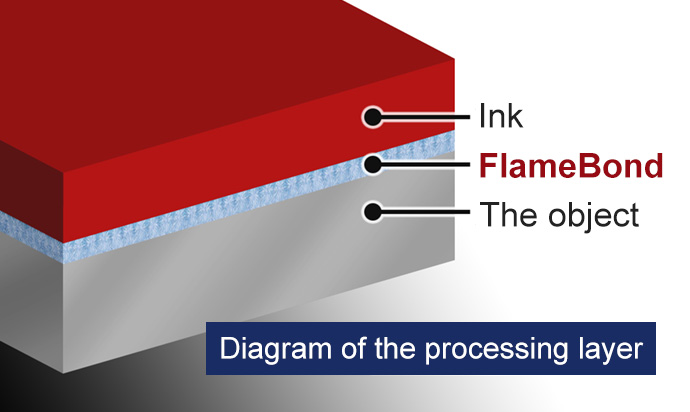

FlameBond is a revolutionary surface modification treatment system that can be quickly applied to materials that have poor adhesion properties and therfore are difficult to print on. By spraying a combustion flame mixed with an organic liquid metal modifier on the surface, a highly hydrophilic silicon oxide layer is formed on the surface of the object at nano-level, greatly improving the adhesion between the surface and the ink.

By performing the "FlameBond" process on materials that have been difficult to print on up to now, the fixability of ink to the material surface is improved, so there is no change in appearance due to the base treatment, and clean design printing on the surface of poorly adhesive material is possible. In addition, it can handle a variety of printing techniques, such as inkjet printing and silk printing, so that the possibilities for your business have been expanded. -

- Diagram of the FlameBond process layer formation

-

-

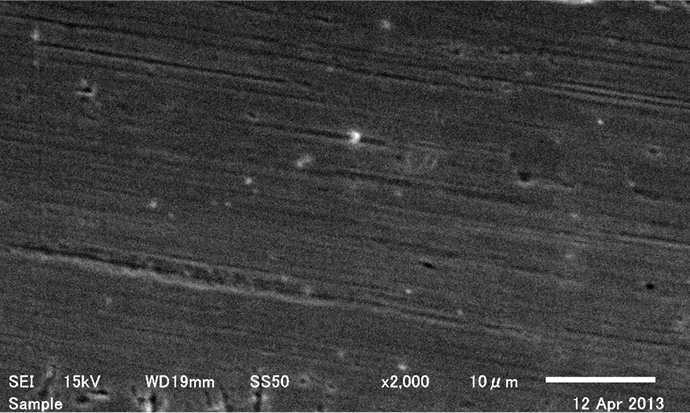

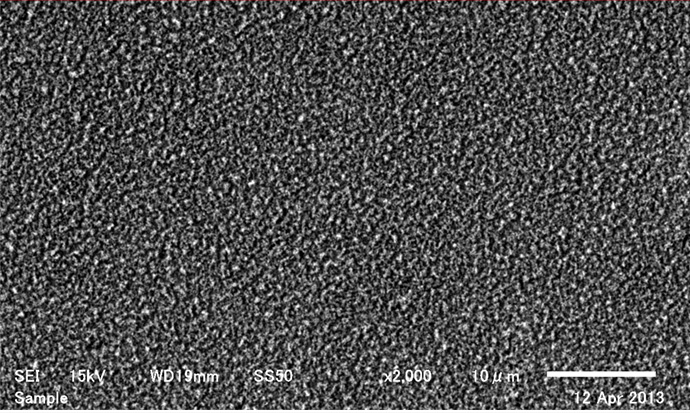

- Surface state of the processing surface

- Before application

- After application

- Base Material SUS430 Electron microscope. Magnification: 2000 times

- Target materials

-

・ Plastics (acrylic, polycarbonate, polypropylene, PET, nylon, etc.)

・ Metal (stainless steel, aluminum, plating treatment substrate, coating plate, etc.)

・ Glass materials (plate glass, heat-resistant glass, hard glass, etc.)

・ Tiles, ceramics

・ Wood-based materials (synthetic wood, bamboo, plywood, etc.)

・ Rubber/elastomer (silicon rubber, EPDM, natural rubber, etc.)

・ Other poorly adhesive materials

* Results may vary due to the application environment and the material used.

Results

- FlameBond Features

-

- Advantages of Flame Bond

- Superhydrophilic effect repels water and improves adhesion

- Quick application time

- Simple overall application process

- The appearance of the material does not change after application, therefore the quality of the material is not lost.

- It lasts for a long time

- Eco-friendly treatment methods without VOC

Performance test

-

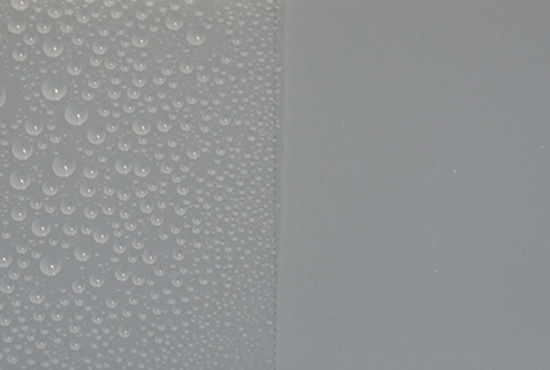

1. Hydrophilia test

The FlameBond treatment creates a hydrophillic layer, which attracts water. It is super hydrophilic with a contact angle of under 10 degrees!

It is this characteristic that greatly improves the adhesion between ink and the surface. -

- Acrylic

Without

applicationWith

application

-

Polypropylene

Without

applicationWith

application

Hydrophilic ability test

The FlameBond treatment is performed only on the right side of the test piece, and the surface condition is shown by applying water to the whole surface.

- Acrylic

Without

-

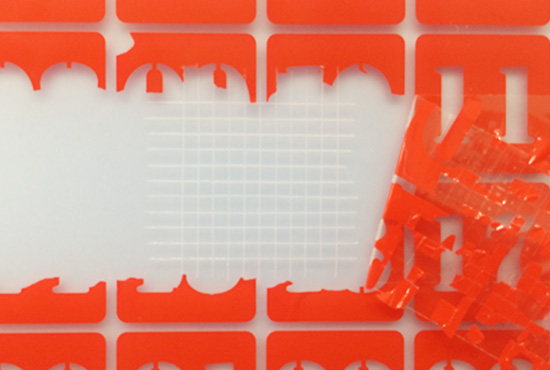

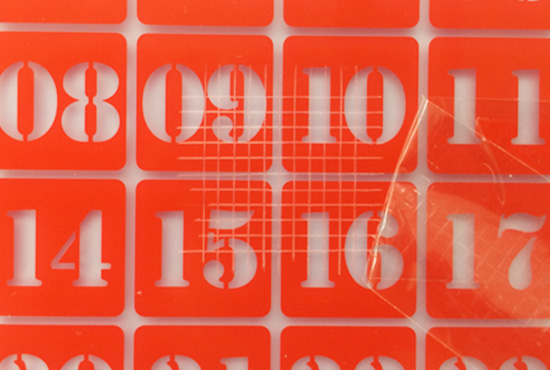

2. Ink adhesion test

The area of the test piece printed on after FlameBond has been applied has no peeling because the ink has adhered firmly to the surface.

In this way, even materials that have been difficult to print on in the past, and materials that previously required multiple treatments in order to be printed on, can now be printed on simply by applying FlameBond. -

-

Without application

-

With application

Peeling test based on JIS K-5600

The FlameBond application process performed on a polypropylene test piece, and after performing silk printing from the top, the results of the peeling test can be seen.

* Results may vary due to the application environment and the material used. -

Without application

Examples of use

-

Silk printing on glass.

It is possible to print without the use of special heat-dried paints. -

Inkjet printing on tiles.

Detailed designs can also be reproduced well.