The semiconductor and IT industries are also using technology from SOFT99 Group.

Precision Electronic Equipment, Semiconductors, Production Processes

- In the semiconductor industry, the various precision components used in electronic devices are becoming smaller and more sophisticated in order to respond to the rapid evolution in the performance of smartphones and other electronic devices, and the quality control required in the production process is becoming more and more strict.

AION is improving research, development and production technology to meet these more accurate demands.

Water absorption, suction, transportation

-

With a fine continuous pore structure, high porosity and water absorption, the absorbent properties, retention, and soft texture exhibit high-performance functions.

To be used with printed circuit boards, for water absorption and transport, with materials such as lead frames, plating, strong acids such as liquids used in etching processes, as well as strong alkaline liquids, in all areas of production. AION make a wide range of products in accordance with strict requirements for high accuracy in conditions such as temperature or humidity. -

AION PU Sponge

AION PU Sponge

A special polyurethane sponge with a fine continuous pore structure and excellent water absorption and liquid absorption. AION PO Sponge Roller

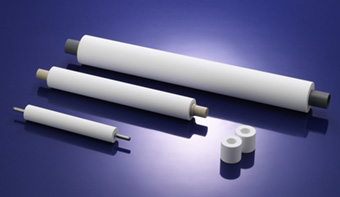

AION PO Sponge Roller

Olefin-based sponge roller with outstanding liquid absorption, which can be used even in strong acid and strong alkaline solutions. AION Floras Sponge

AION Floras Sponge

Fluorine-based sponge roller with a continuous porous structure that has excellent resistance to strong acids, strong alkaline solutions, oxidizing agents, etc., and can be used for liquid cutting, coating, transport, etc.

Precision grinding engineering

-

In the polishing process of aluminum substrates for hard disks, it is very important to polish the substrate precisely to make it a smooth with a mirror finish. The abrasive stone with excellent porosity and elasticity has a solid abrasive grain, leaves no deep scratches on the workpiece, is less likely to generate abrasive heat, and is less likely to clog, so it provides stable performance even for long periods of continuous work.

-

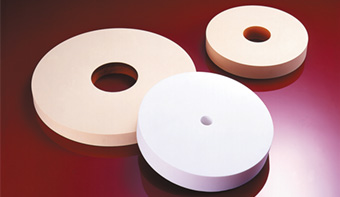

Crystal Whetstone

Crystal Whetstone

This has continuous and high porosity to retain many particles, with a flexibility capable of obtaining a very uniform and high-precision finish. Crystal Buff

Crystal Buff

This is a porous buffing material capable of efficiently obtaining an excellent finish surface by high retention of abrasive grains.

Precision cleaning process

-

The efficient removal of particles and the high-precision cleaning of precision components such as hard disks and silicon wafers greatly affects the quality of the product. It can be processed into rollers, sheets, and blocks, and can be used in various applications in production equipment as multiple different pore diameter products are available.

-

AION Brush Roller

AION Brush Roller

This PVA sponge brush is recognized worldwide for its unmatched performance as a cleaning material for precise electronic components such as silicon wafers and hard disks.

The surface has a soft and elastic protrusion identical to the base material.

The material's excellent abrasion resistance, soft texture and surface protrusions make it extremely efficient at removing tiny particles without damaging the fragile workpiece.

We also have a high cleanliness SCL grade to meet the ever-growing needs of the electronic components industry.

IT: Fault monitoring of substation equipment - Remote monitoring -

-

Receiving e-mail notifications when there is a power failure in substation equipment.

When there is an unexpected halt in the production process, the product value will be lost, and it is likely the product will have to be dismantled and remade. Keeping a constant power supply is very important for the manufacturing process.

Since the power in the factory facility is received at a high voltage from the electric power company, the role of the substation equipment in the facility is very important, and is patrolled 24-hours a day staff. By introducing a remote monitoring device using Haneron's technology, we reduce the human burden on plants and provide a sense of security through e-mail reporting.

T-Scope 4D

T-Scope 4D

This is a compact monitoring device with NTT DOCOMO LTE module.

It is most suitable for monitoring equipment, equipment failures and leakage.